Using the example of a building in the City of London, Gareth Roberts of Sturgis Carbon Profiling explains how new European standards for whole-life carbon assessment can make big savings

01 / INTRODUCTION

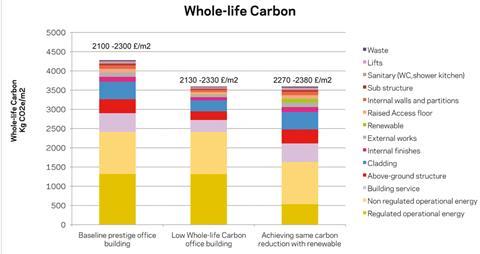

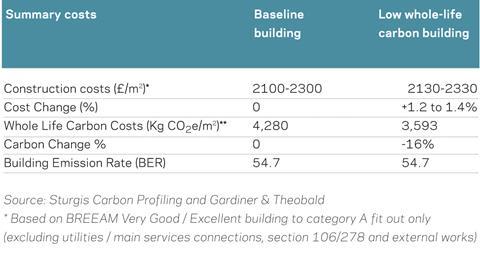

Careful specification in the design of cladding systems, coupled with some other simple measures during construction and procurement, can reduce the whole-life carbon footprint of a prestige office development by over 16% for a cost increase of no more than 1.4%.

This represents a 7% saving in construction costs in comparison to delivering the same level of carbon reductions through renewable energy technologies.

This article previews the new CEN/TC 350 European standards for whole-life carbon assessment, and demonstrates the potential to deliver carbon and cost savings in prestige office developments through this process.

It provides a breakdown of the emissions associated with a typical building in the City of London (although many of the measures identified will be applicable in other locations), both before and after incorporating some of the low-carbon value engineering options.

Some of the issues whole-life carbon addresses are:

- Is it better from a carbon perspective to demolish an existing building and replace it with an efficient new building, given the additional construction emissions generated?

- How do we balance the carbon emissions generated in producing materials against the carbon savings achievable through improved lifetime building performance?

- How can we avoid unintended consequences of over-specification and avoid specifying materials and components that create excessive maintenance and repair liabilities in the future?

- What are the benefits of sourcing materials locally? Is getting the design right more important?

- How do the benefits of improved thermal mass compare with the costs of a more substantial structure?

With investors becoming increasingly risk averse and focusing on the best-performing assets - and tenants looking to reduce operating costs and comply with the CRC Energy Efficiency Scheme - new developments today are expected to display green credentials and many feature innovative ways of reducing the energy used in operating and occupying buildings.

Yet this operational energy accounts for only part of a building’s whole-life carbon emissions.

As successive changes to the �ǿմ�ý Regulations continue to drive down emissions from regulated operational uses, the carbon embodied in construction materials and processes will become more significant as a target for reducing emissions further.

Meanwhile, in the prestige office sector, high churn rates, shorter leases and the risk of functional and aesthetic obsolescence keep the effective life of much building fabric far below its potential design life.

Refurbishment and fit-out cycles lead to an increase in the whole-life carbon footprint, as replacing components incurs emissions from not only the manufacture and installation of new products but also disposal of old ones.

02 / WHOLE-LIFE CARBON ASSESSMENT

Although not yet part of the mainstream construction process, whole-life carbon assessment has some influential friends, including the government’s chief construction adviser Paul Morrell.

In autumn 2010, Morrell’s innovation and growth team report called for its inclusion in the Treasury green book as soon as possible, and for a common methodology to be developed allowing embodied carbon to be taken into account in all design and scheme appraisal.

In response, the government announced its construction strategy last May, requiring the whole-life carbon emissions from all government projects to be managed through building information modelling by 2016.

Meanwhile, a common methodology is due to arrive in the form of the CEN/TC 350 standards for sustainable construction, which will provide a consistent approach to measuring the whole-life carbon emissions of building projects throughout Europe.

The first part of the standards, EN 15804, was published early in 2012 and establishes product category rules for environmental product declarations.

This should help to ensure that construction products are accompanied by certified and comparable information about the level of embodied carbon that they contain.

03 / ASSESSMENT METHODOLOGY

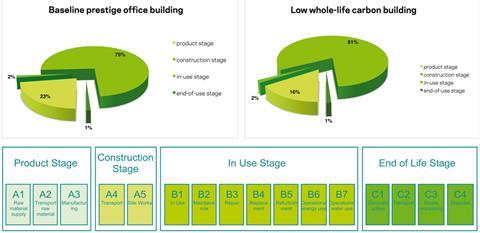

The whole-life carbon cost models in this article are based on the new CEN/TC 350 family of standards. CEN/TC 350 identifies four stages in the life of a building - product manufacture, construction, in-use and end-of-life - with more detailed subcategories used to pinpoint specific sources of emissions.

The first encompasses the extraction of raw materials, their transport to a point of manufacture and the process of transforming them into construction products.

The second involves transporting construction products to site and the on-site processes involved in assembling them into a building.

The third, most complex, stage covers the maintenance, repair, replacement and refurbishment cycles of the building as well as the use of energy and water during its occupation.

In the final stage, the building is deconstructed and redundant components transported off-site, processed and disposed of.

At each stage, whole-life carbon analysis can identify solutions with lower carbon impacts, delivering considerable savings. Recycling benefits should be included at “product stage” but not “end of life stage”. Future recycling benefits should not be included and can only be reported separately.

04 / WHOLE-LIFE CARBON COST MODEL - PRESTIGE OFFICES

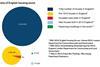

The baseline building for this cost model is an eight-floor 50,000 ft2 speculative prestige office in the City of London, built to a Cat A specification with a net to gross of 80%. The building is fully compliant with the current BCO Guide to Specification.

To aid comparison, the low carbon cost model is based on the same building with the addition of low carbon value engineering options.

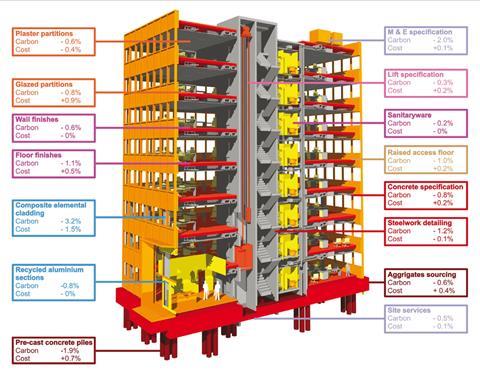

To optimise the building’s whole-life carbon performance, the 50 most carbon-intensive components are first identified.

Each component is then examined to see whether materials of a lower carbon content could be substituted, or if products can be sourced closer to the site or assembled by a more carbon efficient process.

For some products, such as insulation, the relationship with operational emissions needs to be considered in order to avoid over- or under-specification.

These specification choices require dynamic simulation, in which the impact of improving operational performance is considered with respect to the embodied carbon required to achieve it. This marginal analysis often leads to less material specified than if each product was considered in isolation. Examples of these choices are illustrated in the Focus on Cladding section, overleaf.

The interventions do not require any change to the design or appearance of the building, relying only on procurement and construction detailing changes.

05 / FOCUS ON CLADDING

This section discusses the cladding systems commonly used in prestige office buildings, analysing the cost differentials and carbon emissions associated with each different specification choice.

The baseline building uses unitized aluminium curtain walling, an increasingly popular system due to the simplicity and ease it offers in on-site construction.

The disadvantages of these systems are their high embodied carbon content and their short life span, with frequent replacement cycles adding to the whole-life carbon impact of the building.

Compared to unitized systems, a more elemental approach in which components are assembled on-site adds time and cost to the construction process, but can be cheaper overall and reduce the embodied carbon content.

Elements can be replaced separately as they wear out, and refurbishment can be phased to coincide with the end of individual tenancies. A typical life span of the system would be 20-30 years.

Careful design and specification of building envelopes can offer substantial carbon and cost saving hand in hand, as illustrated in the option analysis above.

Consideration however needs to given to the impact on operational energy requirements as not always the best operational performance is the lowest in whole life terms.

06 / KEY FINDINGS AND BENEFITS

- Whole-life carbon measurement offers a simple way to evaluate a range of different design problems by taking account of all the carbon costs and benefits over a buildings life.

- Significant carbon reductions of a buildings whole life footprint can be made by targeting embodied carbon, in addition to renewable and operational energy efficiency improvements.

- Embodied carbon as an allowable solution will help reduce the burden on housebuilders and commercial developers to comply with the forthcoming Part L 2013 and 2016 carbon reduction requirements.

- As the CEN/TC 350 standards emerge, companies with experience in whole-life carbon assessments will enjoy a competitive advantage throughout the EU.

- As the construction industry tries to to achieve the target 80% reduction by 2050, whole-life carbon assessment will be vital in identifying the most cost-effective ways of doing so.

- Demonstrating embodied carbon reductions on projects to local planning authorities can be used as an alternative to delivering emission reductions through renewable technologies in a more cost effective way. SCP has achieved this on three high profile central London projects.

Please see PDF attached for the full whole-life carbon cost model on prestige offices

Acknowledgements

Whole-life carbon cost models have been produced by Sturgis Carbon Profiling, and construction costs provided by Gardiner & Theobald.

More information on compiling a Whole Life Carbon Assessment is available in Whole Life Carbon and Offices (British Council For Offices, 2012). Special thanks to Dr Qian Li, Alastair Wolstenholme and Richard Francis.

Downloads

Whole-life carbon cost model - Prestige offices

PDF, Size 0 kb

1 Readers' comment