British Standards recommend conditions of 15·5°C ±2·5°C and 60%±5% relative humidity for the storage and exhibition of archival documents. Achieving these conditions has more often than not entailed the installation of full air conditioning but the Jersey Archive building uses a pioneering passive approach. What's more by eliminating the mechanical cooling and ventilation systems the client was able to achieve considerable savings in capital outlay and running costs. Plantroom space that is typically 25% of the archive service floor area would also be dramatically reduced, as would infrastructure costs.

The theory

When it came to designing the 800 m2 repository for the Jersey Archive Chris Twinn, associate director of Arup Associates believed that the conditions recommended in BS 5454:1989 could be attained using the moisture fly wheel effect. "Fluctuations in room temperature and humidity can be smoothed by using the building's fabric to absorb moisture and heat during periods of excess, particularly in the summer, which are then re-emitted when the conditions are appropriate" explains Twinn.

Computer based analytical techniques for predicting the thermal dynamic performance of passive building materials are readily available, however at the time of design there was no such software on the market for predicting the potential of the moisture effect. Arup set about developing an analytical tool that would allow it to establish the full extent of the moisture effect.

The moisture algorithm it developed was combined with the Oasys ROOM dynamic thermal software to allow simultaneous room temperature and humidity modelling. A computer model of the repository was used to test combinations of building components to establish their thermal and moisture performance.

The modelling indicated that room environmental conditions could be maintained within the limits of BS 5454: 1989 for the summer peak design conditions. "The results showed that the progress of moisture as it is absorbed by a typical building material is considerably slower than that expected of absorbed heat" says Twinn. In principle the initial 100 mm of moisture penetration is achieved in a time scale measured in weeks, with the subsequent 100 mm responding over many months. Therefore for a heavyweight construction a proportion of the summer room air moisture excess can be absorbed for subsequent emission during winter room air deficiencies, effectively creating an annual flywheel effect.

Airtightness of the repository block was critical. The normal rates of air infiltration in UK buildings would soon overwhelm the speed with which the building material could absorb or emit moisture, as would the air change rates of a mechanical ventilation system. An optimum air infiltration rate of 0·05 air changes per hour (1·2 air changes per day) was selected.

Including a representation of the stored archive material – which is purposely held in cardboard as opposed to plastic boxes – in the computer simulation demonstrated the significant contribution that it has. "On the daily time scale it appears that the archive material provided the bulk of the moisture stability effect" comments Twinn. This is largely due its higher absorption rate.

Controlled natural ventilation is used in combination with the moisture and thermal flywheel effect. When the outdoor absolute moisture content is less than inside introducing ventilation can remove room excess moisture, and equally the opposite is true. Temperature differences between the inside and out can also be useful although for this application the moisture needs have a priority. A building management system linked to motorised vents in the north and south facing walls of the repository building monitors internal and external air temperatures and moisture contents. This then determines when ventilation will be beneficial.

The building layout

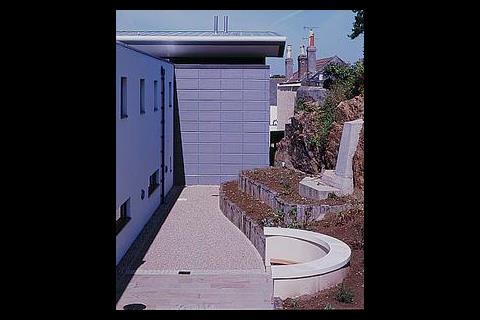

The 1885 m2 development is situated in a former quarry close to the centre of St Hellier in Jersey. The grant funded building is arranged in three blocks. The fully glazed double height reception and exhibition gallery occupy the site's narrow entrance, and act as a shop window for the archive. From the foyer block extends the two-storey public and administration block. The ground floor accommodates the education room and support areas for the archivists and restorers. The first floor is linked via a staircase in the reception/exhibition area and provides public access to the reading room, effectively an oak clad box cantilevered out over the south edge of the ground floor. This space can accommodate up to 20 visitors seated around a central desk where they can view documents retrieved from the archive. Natural light in the reading room is maximised by the installation of clerestory glazing and two strips of windows. As you proceed through the first floor there are further ancillary areas for the staff, which link to the four-storey repository block.

Construction of the repository

The repository block has been built to maximise the moisture and thermal flywheel effect as well as achieving high levels of airtightness. "Jersey still uses a lot of dense concrete block, which has almost disappeared in the UK" says Twinn. It made sense to use this on a number of counts, namely it absorbs more moisture than lightweight blocks as the moisture is stored in the material as opposed to the voids and, as it is a load bearing blockwork, it means that the floor slabs can bear directly on to the blockwork and reduce the effect of shrinkage cracks which could cause outside air infiltration. A vapour barrier surrounds the outside of the 440 mm thick block wall. South and west facing walls are protected against sun exposure by 100 mm of thermal insulation with a 50-75 mm ventilated cavity that is shielded by an outer rain/sun screen.

The thermal performance of the zinc monopitch roof has been enhanced by including 200 mm of insulation together with a fully ventilated roof cavity. To further reduce radiant heat transfer an aluminium foil type low emissivity finish is provided to both faces of the cavity.

A perimeter lthw pipe runs around each floor of the repository to provide background heating. This is 100% welded to prevent any leakage and was chosen to prevent localised high temperatures.

The pressure certified vents in the repository block were chosen to cope with the Inergen gaseous fire suppression system that has been installed which displaces 40% of the air within the archive space when it is activated. These are fitted with simple 25 mm filters that are as much as anything to keep insects out. The question of pollution did arise but it was found that in comparison with a mechanical system only a thirtieth of the amount of fresh air is being introduced. On entering the lobby on each floor of the repository, sensors activate an over door air curtain which reduces infiltration.

Although the scheme has largely dispensed with mechanical cooling there is an exception. Two cold stores occupy the ground floor of the repository block. These house photographic material, which require low humidity and temperatures to be maintained at around 6°C.

Part of the success of the Jersey Archive project was the support of the client, who was prepared to put forward the £10 000-15 000 that it cost to develop the software. This has turned out to be money well spent, delivering a capital cost savings of over £250 000 and an estimated reduction in annual running costs of £40 000. Could the use of air conditioning for archives soon be consigned to history?

Source

ÐÇ¿Õ´«Ã½ Sustainable Design