The designer is merely required to allow for an 6 ac/h for general ventilation or 10 ac/h in the event of fire (ÐÇ¿Õ´«Ã½ Regulations 1991 Approved Documents B & F), irrespective of the size of car park or the potential fire risk.

There is also an ongoing debate between designers, building control and fire officers, and even some insurance companies over whether or not sprinklers are really necessary.

This debate follows the publication of the amended ÐÇ¿Õ´«Ã½ Regulations 1991 Approved Document B, issued in June 2000, which states, in a way that tends to hedge its bets: '...car parks are not normally expected to be fitted with sprinklers.'

However, sprinklers are sometimes required in buildings at the instruction of the insurance company, and in the case of most Section 20 buildings in London.

This paper aims to highlight the changes that have taken place in the available technology and techniques for the ventilation of car parks, as well as to highlight some of the pitfalls.

Traditional systems

Traditionally, natural ventilation or, in most cases for an underground or enclosed car park, a ducted mechanical ventilation system has been employed to control vehicle emissions and, in the event of a fire, extract smoke.

The normal mode of operation for the mechanical system is to provide 6 ac/h for day to day ventilation to control the level of vehicle CO emissions, or 10 ac/h in a fire situation. In both modes of operation this means of providing ventilation to the car park could be both inefficient and unreliable.

In 80-90% of the time, providing 6 ac/h for vehicle emission control will probably be considered as overkill. For most of their operational life car parks carry very little in terms of moving traffic, consequently, a relatively small amount of traffic pollution is caused and a lower rate of ventilation is necessary.

An average day

A prime example for this is a car park serving an office development. During most of the day there will be very little traffic movement, only during the hours when the offices are opening and closing for business will there be any significant traffic movement.

In a fire situation, providing 10 ac/h is very much an arbitrary approach to providing smoke ventilation and would not be tolerated elsewhere in a building. It is true to say that a car park is usually sparsely populated for most of the time, however, it does carry a potentially high fuel load and is often not so easy to escape from in case of emergency.

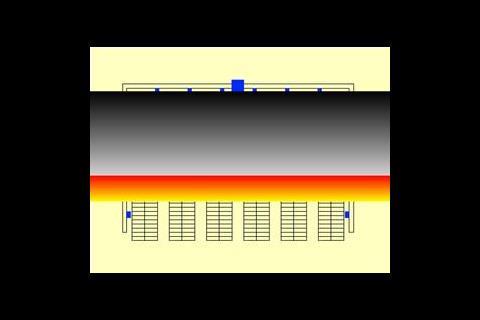

Unfortunately, a car park and a ducted ventilation system does not lend itself to a reliable smoke control system. A ducted extract system will tend to operate more as a smoke dispersal system, drawing smoke towards the various extract grills along the duct branches.

Without the application of an effective zoning system that uses curtains or screens to contain smoke or to maintain its buoyancy for local extract, smoke control becomes impractical.

The options

Systems using jet fan technology, usually associated with tunnel ventilation, are now more frequently seen in the application of mechanical ventilation in basement and enclosed car parks where ducted systems would previously have been employed.

There are two options available for this jet fan type technology a simple smoke dispersal type system and an impulse ventilation type system.

Dispersal systems

The dispersal type system is comparable with the common ducted mechanical system, except it assists in removing ducting and reducing the very high pressure drop associated with a ducted system. In principle, smoke is pushed around by jet fans suspended from the soffit, and dispersed before being extracted via the main extract fans.

Impulse ventilation

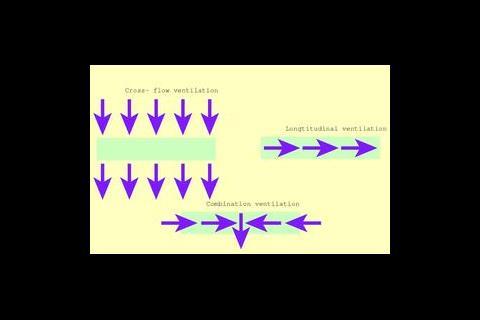

Impulse ventilation uses the latest techniques in tunnel ventilation to control the flow of air, vehicle pollution and smoke flow in car parks.

The impulse ventilation system has three modes of operation: low level – during periods of low traffic movement; high level – during peak periods of traffic movement; and fire level – providing smoke control in the event of a fire.

The impulse ventilation system employs fans to provide the designed airflow rate through the car park, impulse fans to direct the air, smoke and CO sensors to detect air contamination levels and a control system to manipulate the rate of ventilation and airflow direction.

One of the most important features of the impulse ventilation system is that airflow is not determined by air change rates, but on the level of pollution by moving traffic, and on the predicted fire load within the car park.

To comply with ÐÇ¿Õ´«Ã½ Regulations 1991, Approved Document F, CO levels are monitored to ensure ventilation is sufficient so that the average level of CO pollution does not exceed 50 ppm over an eight-hour period.

As a consequence the rate of ventilation can typically vary between 3 ac/h and 6 ac/h – providing a resultant saving in energy consumption and consequent operating costs.

With the advent of new plastics used in the construction of modern vehicles, fire load is a very important element in the design of a car park ventilation system. The basis of an impulse ventilation system design is to create sufficient velocity to overcome the buoyancy of the combustion products in a fire and in doing so, control its passage through the car park.

In this way, the ventilation system is able to contain and control the flow of smoke and protect access to means of escape as well as points of entry for the emergency services.

As the system design is based on a fire load and not on simply an air change rate, it is capable of efficiently coping with large fires.

The impulse type system has already been proven to operate reliably during a real fire situation in an Amsterdam car park. Smoke was contained as predicted and means of escape were protected.

Smoke detection

Fires within a car park are often contained within the shell of the vehicle for a considerable time before heat is released into the car park space. The consequence of this is that there may be no alarm sounded before the fire spreads, which will have implications on the safe evacuation of occupants of the building.

The use of smoke detection alongside fire/heat detection, using multi-criteria heads, means both alarm and smoke control systems can be activated at a much earlier stage than would be the case if initiating the system by heat detection alone.

The use of 'high density' distribution of multi-criteria heads in an addressable system will also permit accurate location of the developing fire. This will permit the efficient localised activation of the smoke extract system as well as assisting the emergency services to quickly identify the location of the fire.

Design for life

Since the publication of the 1991 ÐÇ¿Õ´«Ã½ Regulations, a more engineered approach to the ventilation of underground and enclosed car parks has been developed.

As the potential fire loads from new vehicles increases, so does the burden on designers to identify the weak links in the system. It is now time to design out the inadequacies that exist in the old practices in this area of ventilation. Impulse ventilation may be one answer.

Source

ÐÇ¿Õ´«Ã½ Sustainable Design

Postscript

Richard Brooks is vice chairman of the Smoke Control Association and sales director for PSB-UK, specialist in ventilation systems for underground or enclosed car parks.