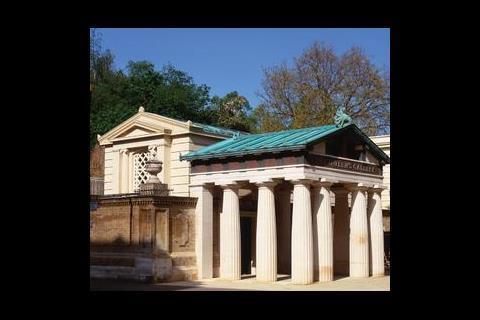

The original Queen’s Gallery was constructed from the ruins of the former private chapel at Buckingham Palace, which was ravaged in an air raid in 1940. Designed by John Nash, the gallery was built on the south west corner of the palace and had been in use since the 1960s. However, it had become unable to accommodate all of the items that the Royal household wished to display and the decision was taken to extend the space.

Faber Maunsell was brought in to carry out an appraisal and value engineering exercise of a design that had been produced previously. An important part of the brief was to be cost-effective while maintaining a quality service. The refurbishment has created three large galleries and three smaller galleries, making nearly four times as much space available. The new galleries were opened by her Majesty on 21 May 2002, in time for the Queen’s Golden Jubilee celebrations. The inaugural exhibition entitled ‘Royal treasures: a golden jubilee celebration’, displaying a collection from eight royal residences spanning some five centuries of collecting.

“Much of the extra space was created by reducing the height of the Royal kitchens and rationalising other poorly organised ancillary spaces, creating a new level for the galleries,” explains Faber Maunsell’s David Waterhouse. “There was also some extension into the gardens, as well as refurbishment of the adjoining three storey block, adding an enclosed plant room for all of the mechanical ventilation equipment.

“The refurbishment was carried out in two phases; beginning with the creation of temporary kitchens to clear the construction site. The old kitchens were refitted and reopened while work continued within the galleries,” he continues.

Services strategy

The reduced height of the kitchens meant that the levels of mechanical ventilation were increased. This was achieved using a ventilated ceiling in the main kitchen and conventional ventilated canopies above main cooking positions in the pastry kitchen. Most of the services to the kitchens are routed through new high level services voids, with piping and cabling to the islands being routed through the network of existing floor ducts.

Fire protection is a major consideration for the Royal household, so in addition to linking the fire detection systems to the main set-up in the palace, fire suppression systems have been installed above the islands and other open flame equipment. The islands are also fitted with break-glasses to shut off electricity and gas in the event of emergency.

Each of the galleries has a dedicated air handling unit providing heating, cooling and steam humidification with particle filtration to EU8 and pollution filtration to remove nitrous oxide, sulphur dioxide and ozone. The control conditions of the space are maintained at a relative humidity of 53% +/- 5%, with temperatures of 20°C in winter and 24°C in summer.

The system uses a variable volume supply with a constant minimum fresh air volume, introduced through floor diffusers with extract at ceiling level. Supply air plenums have been suspended beneath the solid gallery floors to deliver conditioned air to decorative grilles set into the timber floors.

Three 400 kW water-cooled chillers located in a basement plant room provide chilled water to the air handling units, with heat rejection to borehole water via a plate heat exchanger. The borehole was sunk especially for this purpose, and the supply from the heat exchanger is demand-driven, using a variable speed pump.

Heat from the condenser water is used for the first stage of heating in the air handling units, supplemented by medium temperature hot water from the existing boiler room. Provision has been made for future use of condenser water for grey water applications such as garden irrigation.

“This area of the palace combines old and new architecture, creating a complex building that required a high level of co-ordination of services, so a major element of our work was refining the designs to fit the constraints of the building,” David Waterhouse recalls. “For example, the architecture in the shop and entrance area on the ground floor is very decorative and we had to accommodate fan coil units in these areas. The services here are very congested, with pipework being concealed behind the shop finishes, vaulted ceilings and the shop casework,” he adds.

Lighting and fire systems

The lighting of the galleries was designed by lighting consultant, Kevan Shaw. Faber Maunsell was involved in co-ordinating the lighting with other services and between the emergency lighting and the display lighting. In public spaces, the emergency lighting is served by three 6 kW single-phase inverters, while self-contained emergency luminaires have been used in other areas.

“In the larger galleries we are using passive infrared presence detectors to control the lighting for cleaning and security purposes,” explains Faber Maunsell’s Chris Blackman. “In the smaller galleries, separate switching has been installed to switch on pre-selected luminaires for cleaning. Two of the galleries also receive high levels of natural daylight so louvres are used to provide additional control in these areas.”

Fire, data, telephone and the emergency public address system in the galleries have been linked to the existing palace systems and there is a strong emphasis on warden control as these areas will not be occupied unless staff are present. All of the fire systems are fully addressable and incorporate smoke detection and heat detection with sensors being concealed wherever possible.

The new galleries and refitted kitchens are now more heavily serviced than the original spaces and this had a knock-on effect for the power supply, as Chris Blackman recalls: “The extra services were stretching the existing power supply so we added a 1000 kVA sub-station, which feeds the galleries and all of the mechanical plant. We also reconfigured the synchronisation of the two standby generators to provide greater flexibility of back-up.”

Throughout the project, Faber Maunsell were involved in verifying the integrity of the systems and ensuring that ongoing maintenance would be as easy as possible, despite the increase in services. It was also imperative that the project be completed on time so that the new galleries could open in time for the golden jubilee celebration.

“There was a lot of emphasis on testing, commissioning and proving during both phases of the project,” David Waterhouse notes. “This was achieved despite the condensed commissioning phase and the lack of flexibility on completion date,” he concludes.

Source

�ǿմ�ý Sustainable Design

No comments yet