This message has particular resonance for the building industry: more than 50% of all UK emissions are generated by the construction and subsequent use of buildings. Many projects, especially large-scale office developments, consume a huge amount of energy. The main contributors to the problem are lighting, heating, cooling, and power for electrical equipment. Government regulations aimed at improving sustainability insist that designers of new buildings have to consider a range of measures to reduce the energy consumed. These include improving the building's insulation to reduce heat loss, limiting the amount of glazing and the application of reflective coatings on windows to limit solar gain.

These relatively simple measures can make a significant difference but further consideration is required with regards to the energy consumed by a building's hvac system. Furthermore there is a perception that many mechanical ventilation schemes do not behave as well as could be expected, but removing an hvac system entirely will lead to uncomfortable working conditions so this is not considered a practical solution.

The challenge therefore is to harness natural and background energy sources – such as thermal and wind energy – to maintain a healthy and acceptable indoor climate in buildings. As a result, there is an increased interest in the understanding and optimisation of existing natural ventilation strategies. The resulting energy debt of the building will then be notably less than that of the original hvac system.

An obstacle to the wider acceptance of natural ventilation systems is their relatively low reliability and unpredictability compared with conventional mechanical ventilation systems. Linked to this problem are variations in building structures, the influence of outdoor climate and the complexity in the surrounding environment. This makes the design of an efficient natural ventilation system a more difficult objective than that of mechanical counterparts, and requires a more complete understanding of the overall airflow mechanisms.

By modelling the driving forces behind natural ventilation using computational fluid dynamics (cfd) techniques, these uncertainties can be minimised or even removed, providing increased confidence in the final design. After identification, any uncomfortable areas or times of day and year can then be reviewed or complemented with mechanical ventilation.

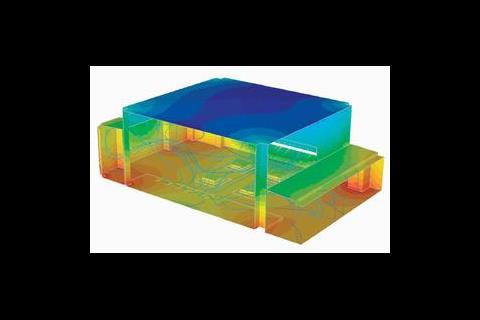

The driving force behind most natural ventilation systems is a combination of the external wind environment and the internal buoyant flow. When designing such a scheme, consideration must be given to the pressure loading on open vents and windows as this drives the airflow into and within the building For different wind directions, particularly the prevailing direction, a clear idea of the external wind distribution around the building is essential. Local buildings and topography influence this distribution; elements that can all be taken into account with cfd modelling and analysis. The orientation of the building itself is also an important consideration, not only in terms of wind distribution, but also when considering solar loading which may be a prime driver of buoyant plumes.

CFD analysis can be used to provide confidence in designs for new approaches to ventilating buildings by natural means, removing uncertainty for clients.

As well as limiting the energy consumed by a building, there are also opportunities within the design to create a building that generates its own energy, allowing a reduction in the running energy deficit, or even to make it energy neutral. Examples of this include the use of solar panels, geothermal energy and, for tall buildings especially, the inclusion of integrated wind turbines in the building structure. The energy created by a wind turbine is proportional to velocity squared so it is important to locate the turbine in an area of high wind speed. The local wind speeds around a building are determined by a number of factors including the prevailing wind direction, surrounding buildings and topography. CFD modelling integrates these features, thereby ensuring that the turbine is located in an optimal place from a wind energy perspective.

The West Winter Garden at Heron Quays in London's Docklands provides a prime example of the application of cfd in optimising a ventilation scheme. GDM Partnership was responsible for the m&e design of the building and they used cfd consultancy services to ensure that the occupants' comfort was acceptable for the proposed ventilation scheme. This included displacement vents, extraction grilles and passive ventilation through open windows. There were also heat gains from solar radiation through the entirely glazed walls and from the occupants themselves. The results of the simulations demonstrated that comfort levels are within acceptable limits with significant ventilation within the occupied zone, giving the designers confidence in the final design scheme.

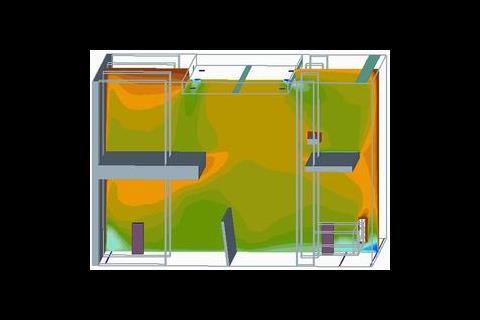

When carrying out a cfd simulation, the geometry of the building must first be modelled and embedded within a numerical mesh. Boundary conditions are then set and the model solved. This overall process may take hours to several weeks, depending on the level of detail and the physical size of the geometry. The post-processor is then used to interrogate the results to display computed variables such as velocity, temperature, pressure or any of the comfort metrics (eg mean age of air, predicted mean vote, predicted percentage dissatisfied). The latter metrics are defined in ISO 7730. The predicted mean vote is a measurement of occupant comfort in moderate thermal environments, based on air temperature, air velocity, radiant temperature, relative humidity and the occupant clothing and activity level. Predicted percentage dissatisfied is another means of demonstrating occupancy comfort using these parameters.

CFD offers a key benefit over conventional calculation methods in that it shows how these figures vary over the zones modelled, rather than simply returning global or average values for whole rooms or buildings. This allows localised problem spots to be pinpointed. It is also key to understanding the cause of any problems in the performance of the ventilation scheme; for example, the engineer can visualise the flow field and trace the flow of hot and cold airstreams.

The real power of cfd is the ability to answer the "what if?" questions that arise, without having to physically test the design first. The flexibility cfd offers allows different scenarios to be investigated. Variables such as air ventilation speed or temperature (possibly resulting from extremes of external climate) can be varied to examine the sensitivity of the ventilation scheme to these parameters – reflecting the importance of ensuring the building remains comfortable at all times. Geometrical variations can also be checked, including changes to the layout of rooms and/or ventilation schemes. In this respect, cfd is a powerful tool for optimising a particular building or ventilation design and reducing the overall energy consumption of the building.

If we are to meet the new targets on greenhouse gas emissions, the construction industry is clearly going to have to make more efficient use of our natural resources. New approaches to ventilating buildings by natural means and providing their own renewable energy are helping to reduce the energy demands of new and innovative buildings. CFD analysis can be used to provide confidence in these designs and also to remove any uncertainty in their performance.

Source

ÐÇ¿Õ´«Ã½ Sustainable Design

Postscript

Steve McCormick is senior cfd engineer, and Daniel Burton is business development manager – hvac, Fluent Europe.

No comments yet