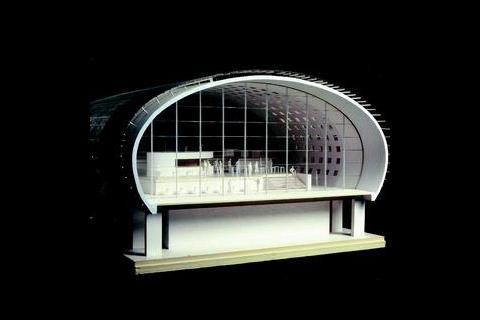

The passenger area is raised above ground level and the space beneath occupied by auxiliary areas. Two banks of high level nozzles situated in the 'windows' of the concrete shell deliver conditioned air, with extract via low level grilles.

CFD modelling consultant Flomerics was appointed to help the client and design team, which included Sechaud-Bossuyt and Rineau, evaluate the proposed design and explore any remedial measures that might be necessary.

Summer and winter simulation

The summer scenario looked at ensuring an optimal thermal comfort level under external conditions of 35°C and midday sunshine. It also looked at the air temperature gradients in the zenithal section to make sure that these did not exceed 35°C, which may cause structural problems in the glazing elements.

To overcome the contrast in scales a separate model was constructed to study the reaction of the double-glazing to the solar radiation. A number of simulations were run to account for the variation in the physical properties of the glass. These results were used in the building model, which assumed a maximum occupancy of 16 people per building slice.

The mean ambient room temperature under these conditions was found to be 25°C. The thermal comfort (Fanger) index maps generated predicted mean values of between –1 and 1, well within the acceptable range of –3 to 3. Figures for the percentage of people dissatisfied showed the majority would find conditions comfortable.

It was envisaged that there shouldn't be any problems with adverse heating of the glazing and associated structure, with the surface temperature of the concrete not exceeding 50°C and that of the the metal 60°C.

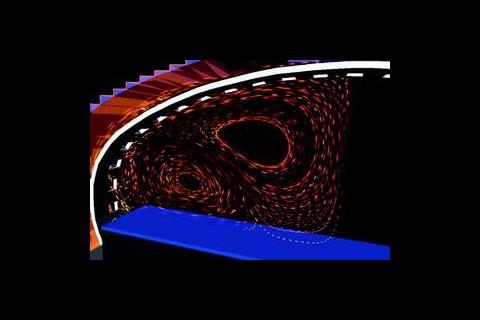

Examining the fluid flow showed a constant circulation of air in the space between the double-glazing and the concrete inner shell with cool air being induced at low level. It also confirmed good homogeneity of temperatures in the whole space and an absence of air stratification.

Detailed work on the blower jets revealed air induction by blowing, cooling the body of air and reducing the temperature divergence between the blown air and the ambient air. The range of the jets was also confirmed and the specific angle of the air delivery nozzles set at 8° for the upper bank and 15° for the lower bank.

The winter case looked at the thermal comfort conditions of the main space, and the air delivery temperature needed to maintain this. A critical case of -10°C external temperature and no sunshine was chosen and a range of supply temperatures simulated. Results of the modelling determined an air delivery temperature of 22°C, confirming the preliminary calculations.

Modelling of the fluid flow showed that air travel was completely reversed from the summer scenario. Air from the main space enters the gap between the glazing and inner shell, cools and travels around the structure to exit at the bottom, thereby creating an insulating layer.

The extract air temperature could also be accurately predicted allowing the heating plant to be sized with a greater degree of precision.

A potential problem area was at the midpoint of the new terminal where it connects with the main airport building. Here the concrete inner shell is omitted leaving only the fully glazed structure. Simulations showed that concerns of overheating under critical conditions could be overcome by optimising the angle of the air jets on either side of the space, thereby eliminating the need for any radical redesign.

Source

ÐÇ¿Õ´«Ã½ Sustainable Design

Postscript

BSRIA and Flomerics are running an open day to illustrate the latest research technologies. Contact 01344 426511.