The Germans (who else?) have designed housing that is 40% more energy efficient than UK ÐÇ¿Õ´«Ã½ Regulations require. BRE's Gavin Hodgson reveals how they did it

If you think the insulation requirements under the new Part L are tough, think again. The BRE is promoting a new type of super-insulated dwelling that is 40% more energy efficient than homes built under the 2006 version of the ÐÇ¿Õ´«Ã½ Regulations. Any home that complies can be labelled a ‘PassivHaus'. The task is so challenging that only two homes come close to the standard in the UK.

For a dwelling to qualify as a PassivHaus, it must comply with two key criteria: first, the home's design must reduce the energy demand and second, the dwelling's remaining energy requirement must be met as efficiently and cleanly as possible. For a true PassivHaus, the energy used for space heating and cooling must be less than 15 kWh/m2/y and total primary energy use is limited to 120 kWh/m2/y - a challenge for any housebuilder.

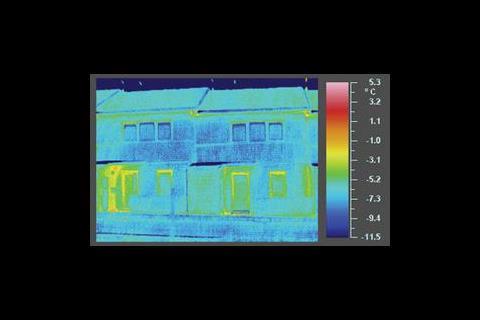

The majority of housebuilders don't fully consider (or indeed understand) the impact airtightness, non-repeating thermal bridging and the correct utilisation of solar gains have on a home's energy use.

The maximum permissible air permeability of a new home under the ÐÇ¿Õ´«Ã½ Regulations, Part L1A 2006, is 10 m3/hr/m2 at a test pressure of 50 Pa). But even at the standard demanded by ÐÇ¿Õ´«Ã½ Regulations, air permeability can account for up to 30% of all heat loss in a new home. The permeability level required by a Passivhaus is 1 m3/hr/m2 at 50 Pa.

The most effective way of controlling the ventilation rate to the levels required by PassivHaus is through the specification of whole house mechanical ventilation with heat recovery (MVHR). To ensure the health and comfort of the inhabitants for such an airtight construction, the MVHR system employed must only use the stale exhaust air to pre-heat the incoming fresh air, without the air flows becoming mixed in the process.

Of course, this only works with counter flow heat exchangers and very energy-efficient ventilators. With this technology, the recovered heat is 8-15 times higher than the electricity needed to power the fans. This will ensure adequate ventilation and dramatically reduce the heat lost through uncontrolled ventilation.

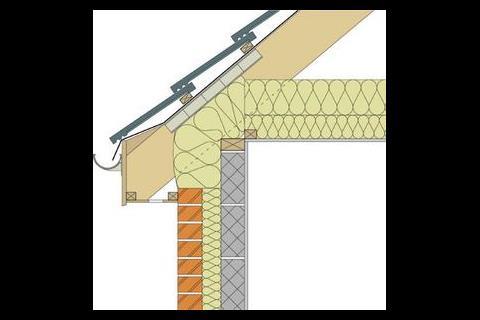

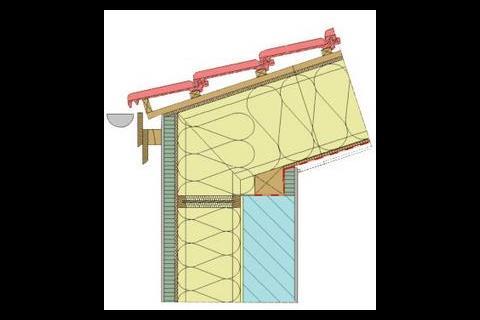

Non-repeating thermal bridges (ie junctions between elements, such as wall-wall, wall-window etc) are not accounted for within the U-values of the building elements and most architects simply accept the default values provided by ‘accredited robust details'. The default thermal transmittance for junctions to accredited robust details is typically 0.08 W/m2K - however, by eliminating all thermal bridges and achieving a thermal transmittance of 0.01 W/mK or lower (in line with the PassivHaus standard) heat loss can be reduced by a further 10-15% on average (see figures 1 and 2).

In addition to these requirements, if the fabric U-values are specified as 0.15 W/m2K for the walls, floor and roof, and the windows and doors are specified as 0.8 W/m2K, then the 15 kWh/m2/y criteria will normally be achieved.

Solar gains are also an issue - and trying to offset poor consideration of these, reduced levels of airtightness or poor thermal bridging by specifying increased fabric U-values will not have the desired effect, meaning the target value is unlikely to be achieved.

Meeting the demand

By dramatically increasing the energy efficiency of a building, via the above steps, the HVAC systems can be radically simplified - a concept developed by Amory Lovins where investment is reduced through energy efficient design.

The most significant investment threshold appears when the peak heating load reaches 10 W/m². At this point, the ventilation system can easily be used for space heating, and a separate heating system is no longer required. This approach will only work in a PassivHaus. There is no immediate benefit in going beyond this and creating an autonomous house as the costs would rise dramatically.

In any building, a 10 W/m² represents a very low heating requirement, but in a PassivHaus, the peak heat load requirement is so low that installing a small 1 kW electric heater into the fresh air inlet is sufficient to gently heat the supply air. If, in addition, the heater for the supply air is integrated within the ventilation system and the domestic hot water boiler, one ends up with an integrated compact unit (see figure 3). In Germany, there are more than 10 providers of such compact units. These appliances are highly efficient - and the monitoring of PassivHaus dwellings in Germany (CEPHUS study) has proven the concept.

An additional opportunity to increase the efficiency of ventilation systems is the use of earth-buried ducts, which preheat fresh air in winter or cool it in summer. This can be done directly with air ducts in the ground, or indirectly with brine circulating in earth buried pipes and heating or cooling the air with a water-to-air heat exchanger.

A variety of other, more traditional, heating solutions are viable, including the use of community or group heating systems - or a single condensing boiler, heat pump or small room heater - but most of these options involve additional provision for fuel supply to the dwelling. So for an individual house, a compact unit is usually the most attractive option.

All these advantages are available if (and only if) the peak load demand is very low - otherwise higher capacities, additional room heaters and flue pipes will become necessary.

In mainland Europe, 4000 homes have already been built to the PassivHaus standard. The significance of these design principles in the UK will increase greatly as further amendments to Part L continue to improve minimum acceptable levels of energy efficiency.

Source

ÐÇ¿Õ´«Ã½ Sustainable Design

No comments yet